Topsides & Hulls

Topsides & Hulls

Offshore Topsides & Hull Piping

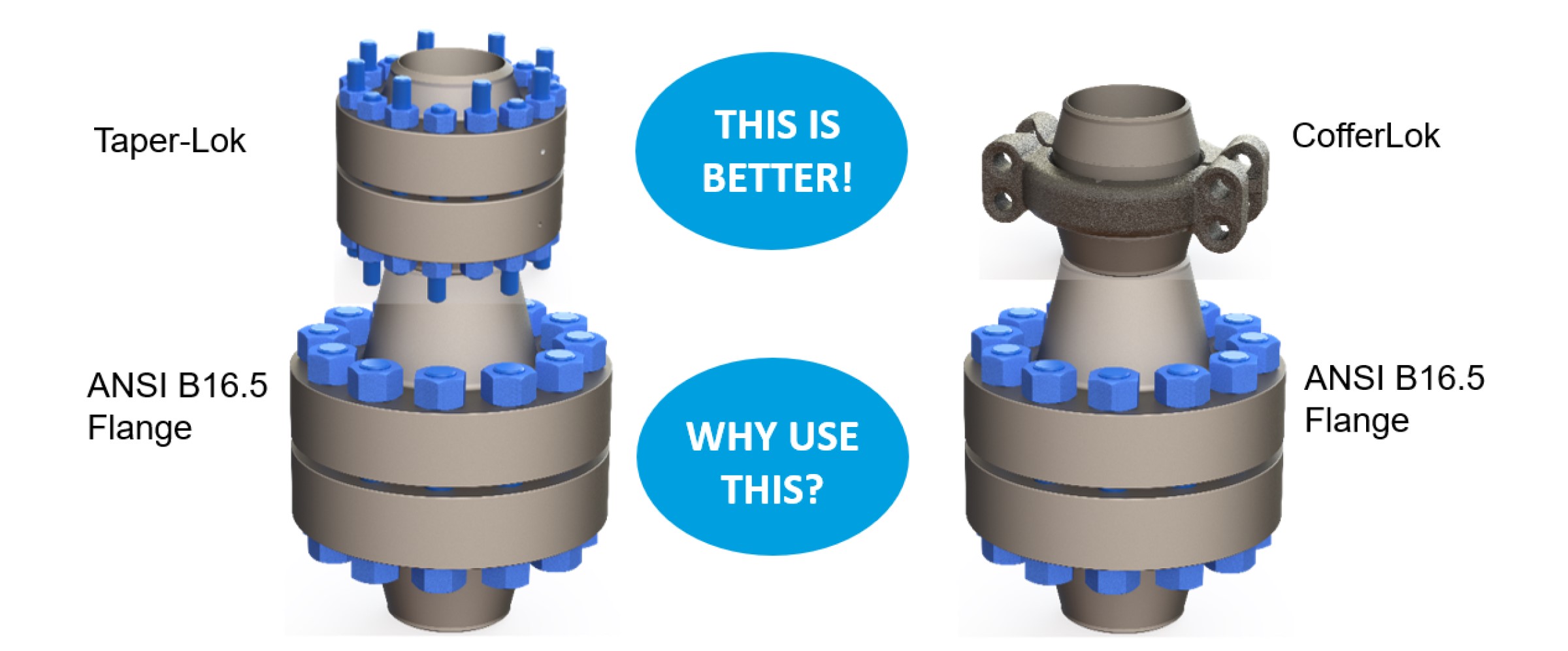

Taper-Lok and CofferLok Compact Engineered Connectors can be used on all topsides and hulls process systems, manifolds, connectors on valves, equipment, boarding valves, skid packages, risers, chemical injection systems and membrane separation systems. When used platform wide in ANSI class 600# and above, typical weight savings of up to one million lbs. can be realized.

Weight and Space Savings

Our Engineered Connectors save weight and space. With weight savings of up to 80% in comparison to ANSI flanges, our engineered connection systems can typically save up to one million pounds on the topsides of an offshore floating platform. These connectors also offer space savings of up to 82% with smaller outside diameter and length dimensions compared to ANSI/API flanges. Pipe runs can be designed closer together to create more room for process equipment and future tie-backs. Our connectors are ideal for small O.D. pull-in-head requirements.

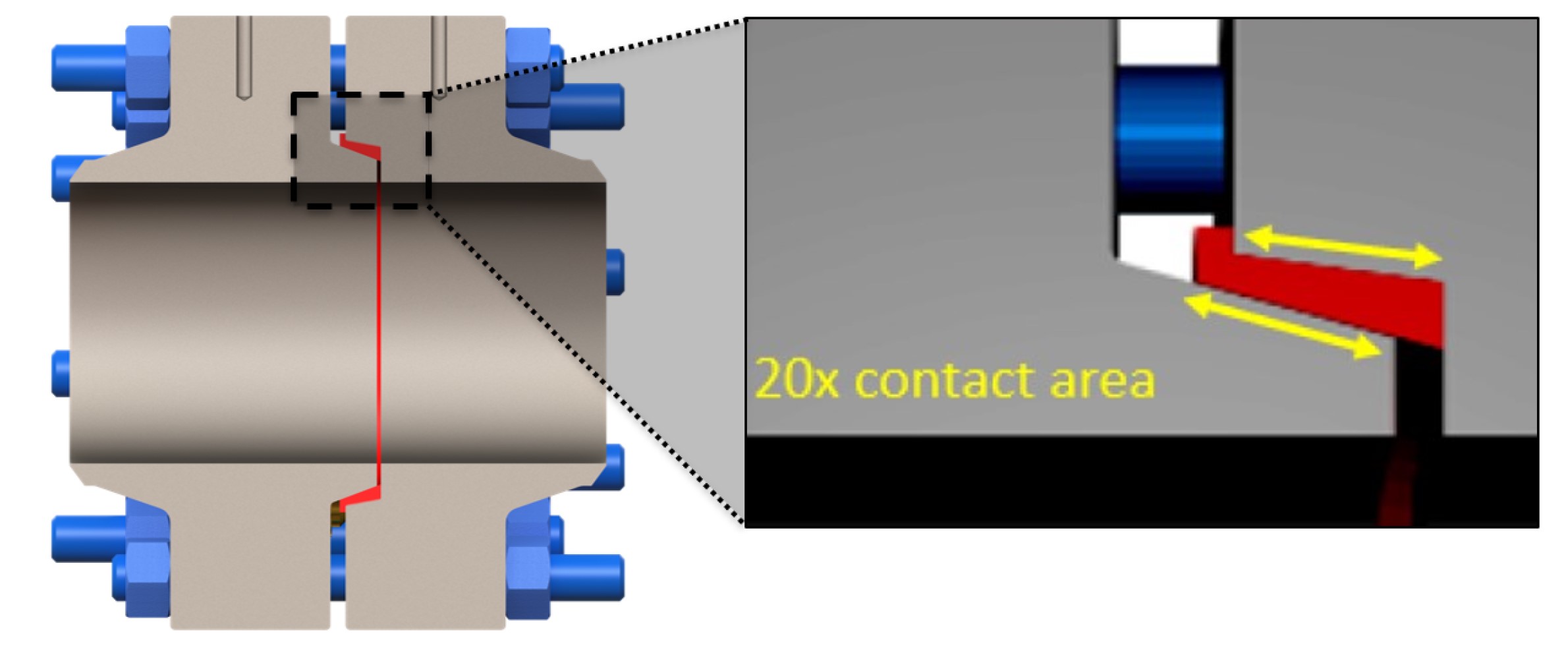

Taper-Lok Wide-Area Seal Technology

Taper-Lok Connectors metal-to-metal seal ring technology offers leak-free reliability over traditional ANSI and API gaskets. Our seal rings offer the equivalency of welded joint integrity and can be used in critical and chronic leak areas. Many “metal to metal” ring type connections rely on a narrow band of contact. In principle, this will be enough, but in practice, in field conditions they are easily damaged. Taper-Lok incorporates a Wide Area Seal that is up to 20 times the contact area of other metal to metal seals. Ensuring a robust and forgiving connection that can easily withstand the rigors of repeated job site connections in tough conditions.

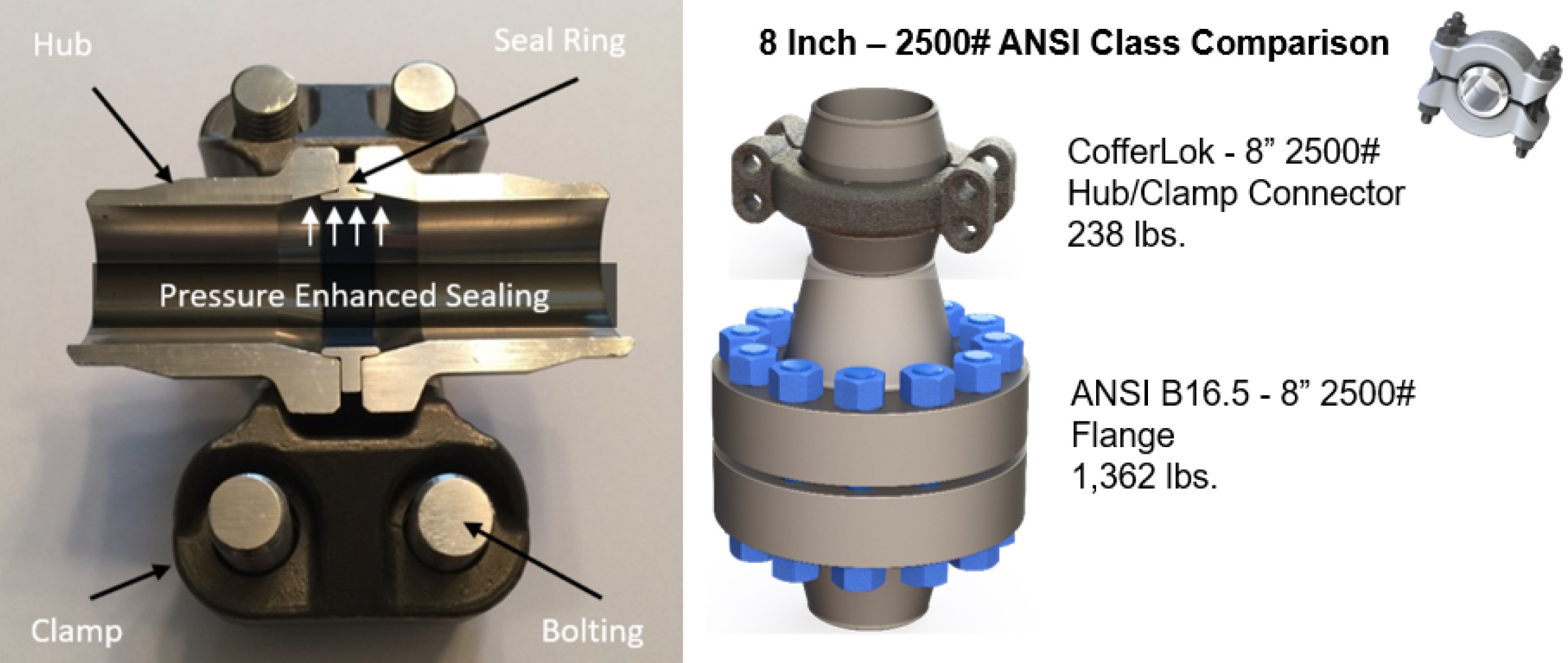

CofferLok Clamp Advantages over ANSI B16.5 Flanges

Self energized and pressure energized seal. Seal ring is designed to be reusable. Small relative movements between hubs can be accommodated by seal ring deflection. Clamp assembly lighter and requires less space. Clamp bolts are oriented perpendicular to pressure end thrust and are not subjected to hydrostatic loading due to pressure. Small outside dimensions allow use in more congested areas. Clamps can be conveniently rotated for desired bolt orientation. Four bolt design has built in safety factor which allows for bolt failure without loss of sealing integrity. The connectors method of sealing does not require precision bolt loading, thus easier to make up. Reliable 1 X10-6 cc/sec leak detection (one part per million)

Topside and Hull Piping Spools

Taper-Lok Connectors with a male/female self-aligning flange configuration install up to 75% faster and easier than ANSI or API flanges. CNOOC PL 19-3 Phase II project was installed 20 days early and saved the client $3 million due to the ease of installation. Taper-Lok swivel and weld neck flanges can come with a spherical nose configuration on the male flange which allows for 2-3 degrees of misalignment.

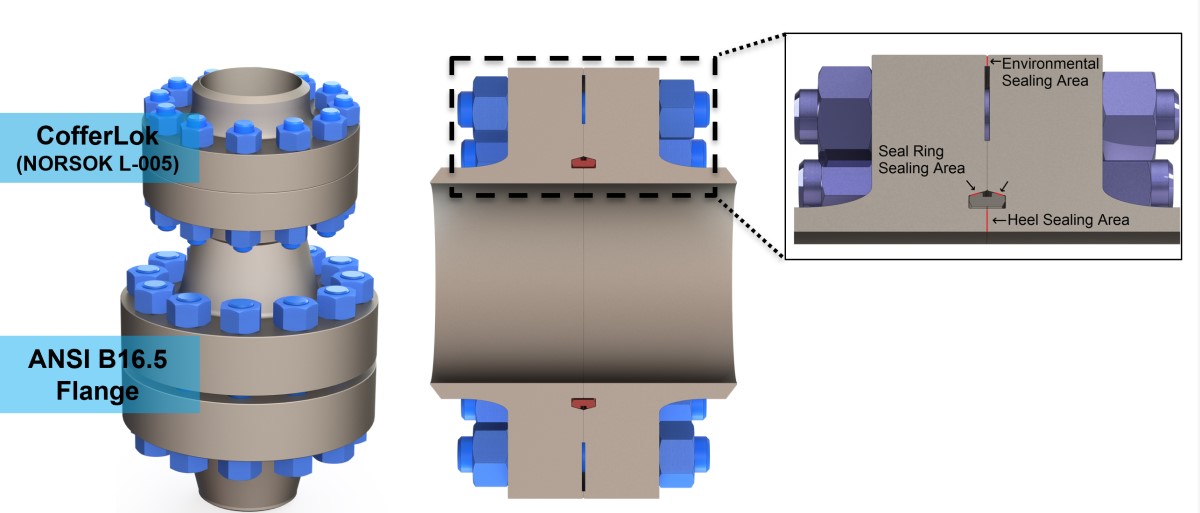

CofferLok Compact Flange (NORSOK L-005)

Offers outstanding benefits whenever size, weight and stress are critical factors in pipe-design. Compared to ANSI Flange connections, CofferLok Compact Flanges (NORSOK L-005) save up to 82% of weight withstanding high bending and tension loads without leaking—No retightening of bolts required—Two independent metal sealing surfaces, a third environmental seal area, and static connection strength—Design codes ASME VIII Div.2 Appendix 4 and 6, ANSI/ASME B31.3, B31.8, BS 500 and API—The NORSOKL-005 standard covers up to 2500# class. 5K, 10K and 15K psi pressures available—CofferLok “E” seal ring is interchangeable with NORSOK IX seal ring—NORSOK L-005 is also known as ISO 27509.

Damage in Seal Area -Not Usually A Problem

Taper-Lok Connectors are the most robust flange connectors in the world . In the pictures shown, damage occurred to the Taper-Lok male nose and the joint still passed hydro-test due to its wide contact area seal design. Taper-Lok’s metal-to-metal seal has 20 x contact area vs. other seals. This means scratches and damage can occur and the joint will still be leak free. This is one reason why Taper-Lok connectors have never had a leak in over 55 years of service.