Petrochemical & Refinery

Petrochemical & Refinery

Perfect for Petrochemical and Refinery Applications

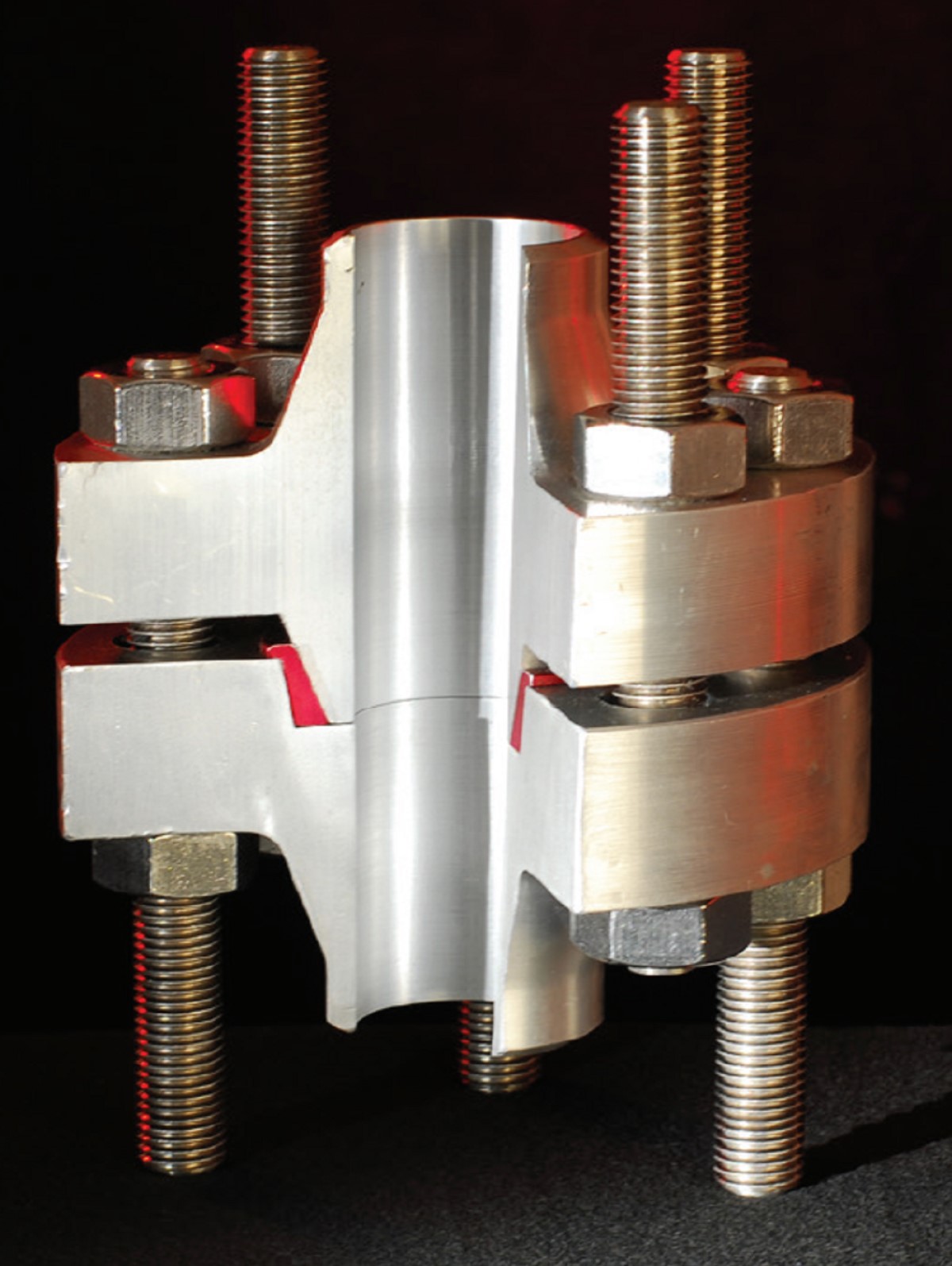

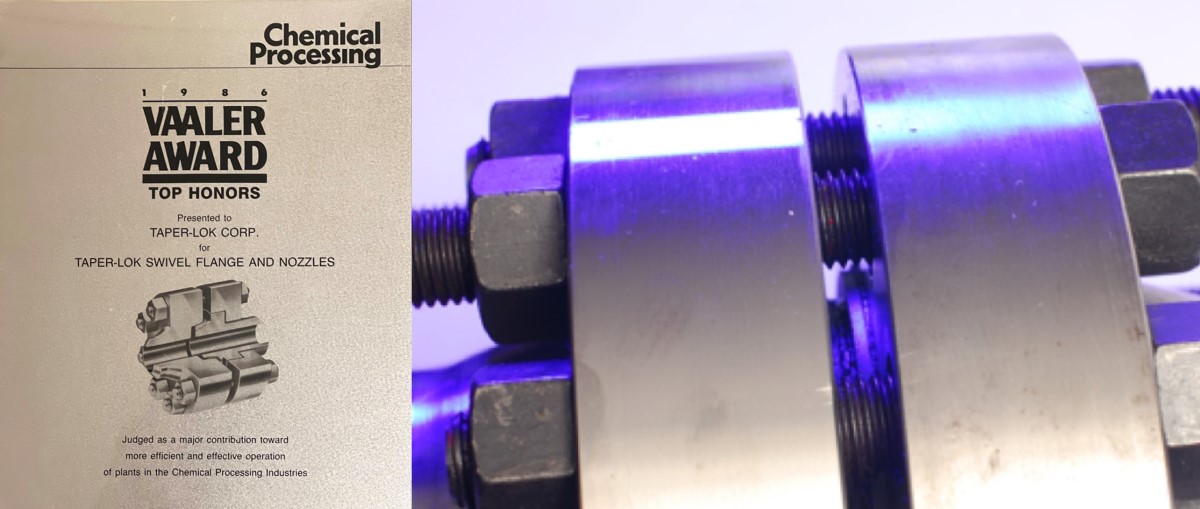

Our Engineered Connectors have 55 years of leak-free service in critical petrochemical and refinery applications. In many cases, our connector assemblies are less expensive to purchase than the corresponding ANSI or API flange assembly. We can retrofit your chronic leaky flanges and exchangers on-site to the Taper-Lok or CofferLok design. These connection systems are even better in high pressure and/or high temperature applications.

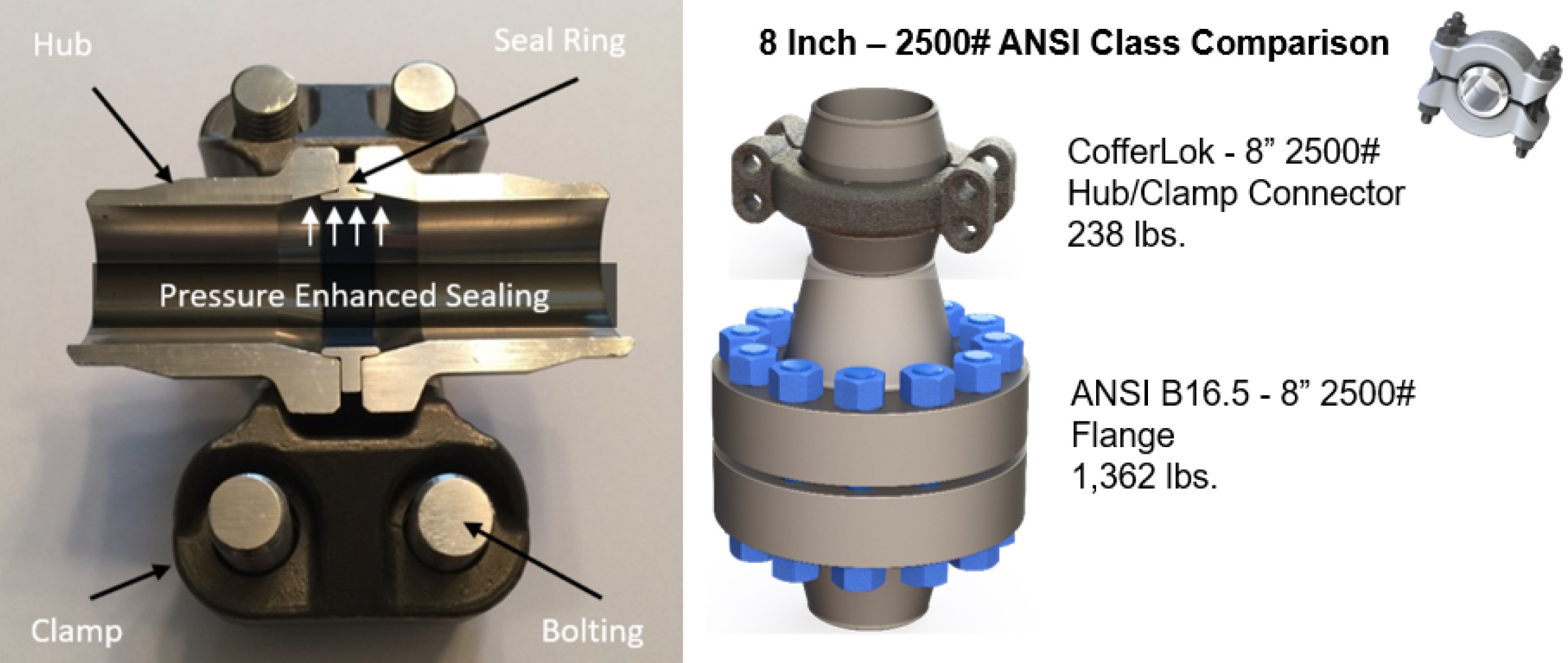

CofferLok Clamp Advantages over ANSI B16.5 Flanges

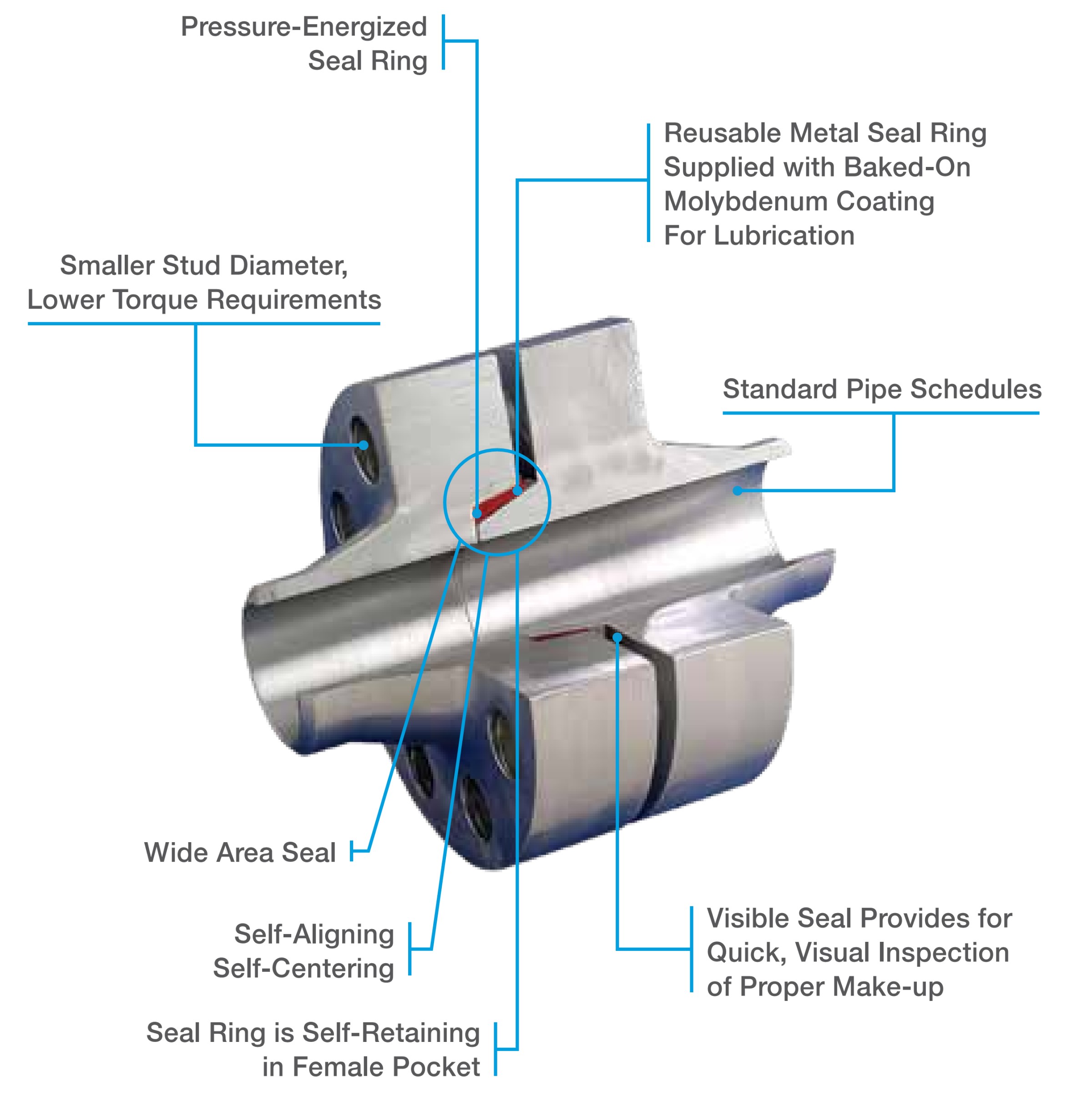

Self energized and pressure energized seal. Seal ring is designed to be reusable. Small relative movements between hubs can be accommodated by seal ring deflection. Clamp assembly lighter and requires less space. Clamp bolts are oriented perpendicular to pressure end thrust and are not subjected to hydrostatic loading due to pressure. Small outside dimensions allow use in more congested areas. Clamps can be conveniently rotated for desired bolt orientation. Four bolt design has built in safety factor which allows for bolt failure without loss of sealing integrity. The connectors method of sealing does not require precision bolt loading, thus easier to make up. Reliable 1 X10-6 cc/sec leak detection (one part per million).

How Much Does A Flange Leak Cost?

Every plant has some type of flange leak. In many cases these leaks are in critical parts of the process. Leaks can cause plant shut downs and cost $millions in lost production. We can retrofit your chronic leaky flanges during your next planned maintenance to our metal seal technology and eliminate leaks.