Connector Benefits

Connector Benefits

Leak-Free Reliability

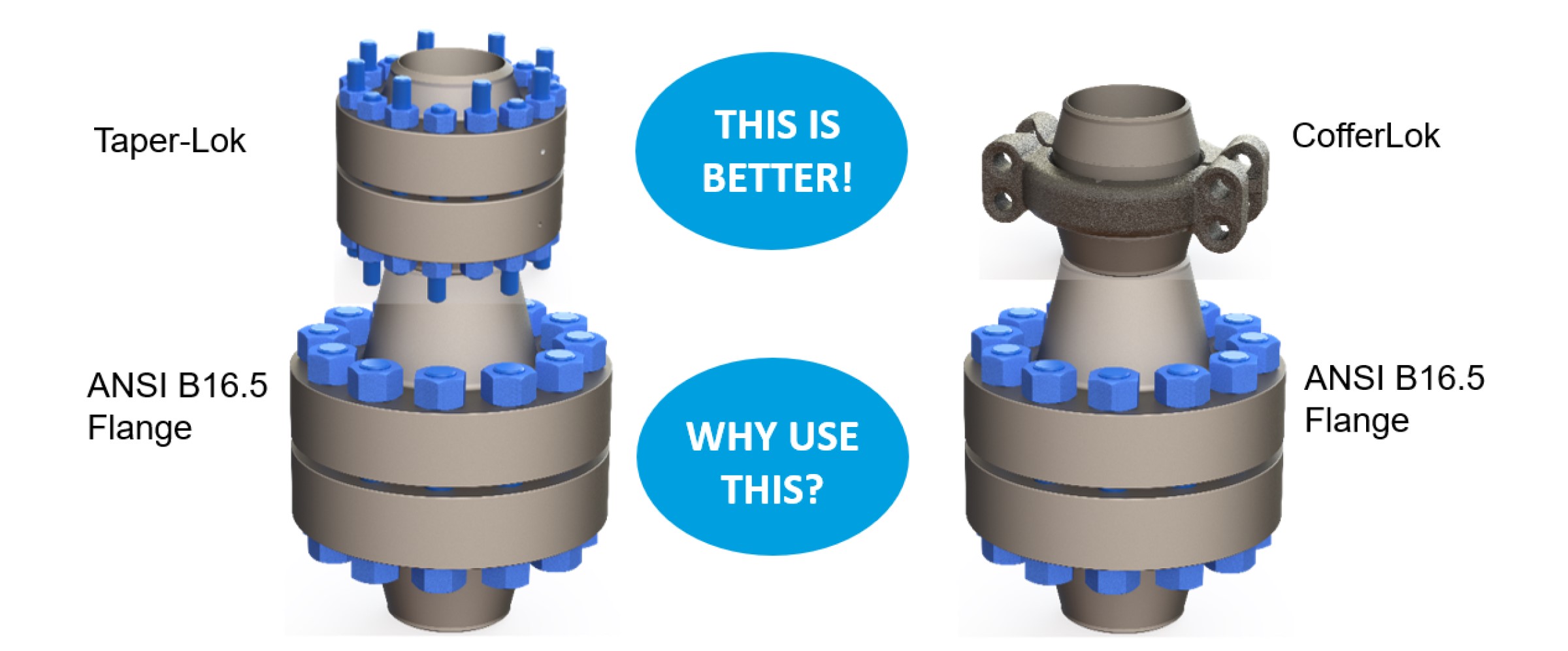

Taper-Lok and CofferLok Connectors metal-to-metal seal ring technology offers leak-free reliability over traditional ANSI and API gaskets. Our seal rings offer the equivalency of welded joint integrity and can be used in critical and chronic leak areas.

Withstands High External Loading

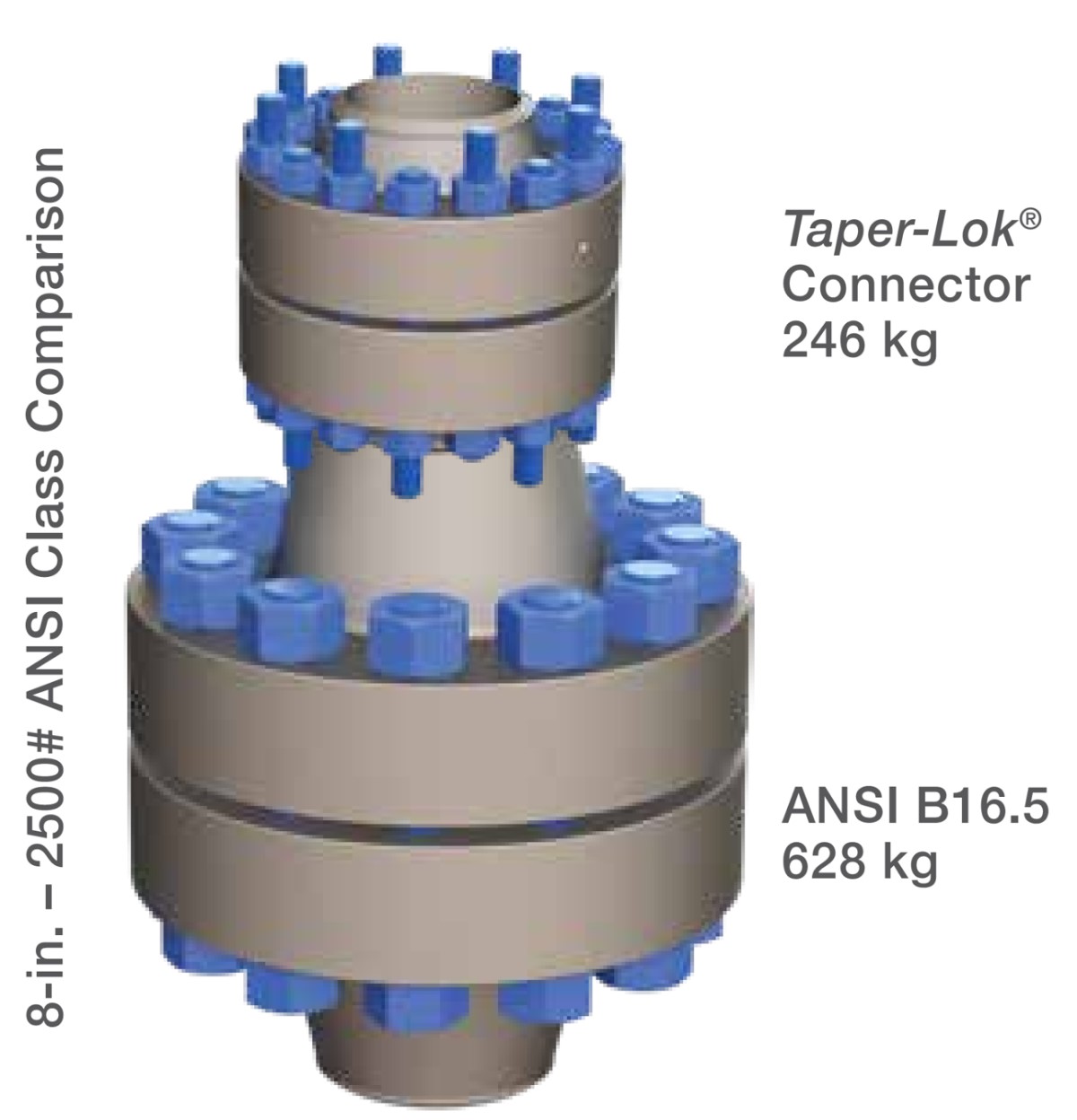

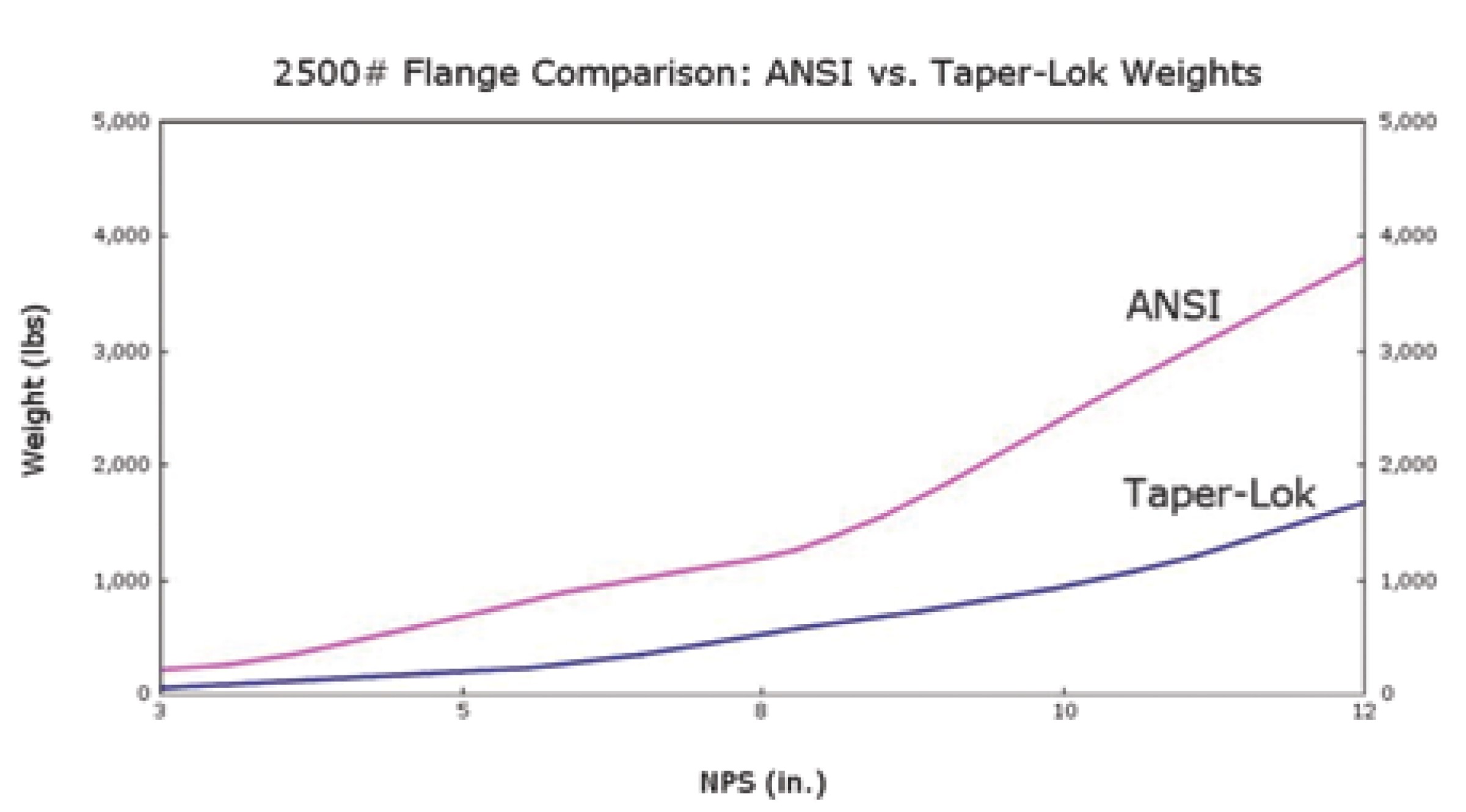

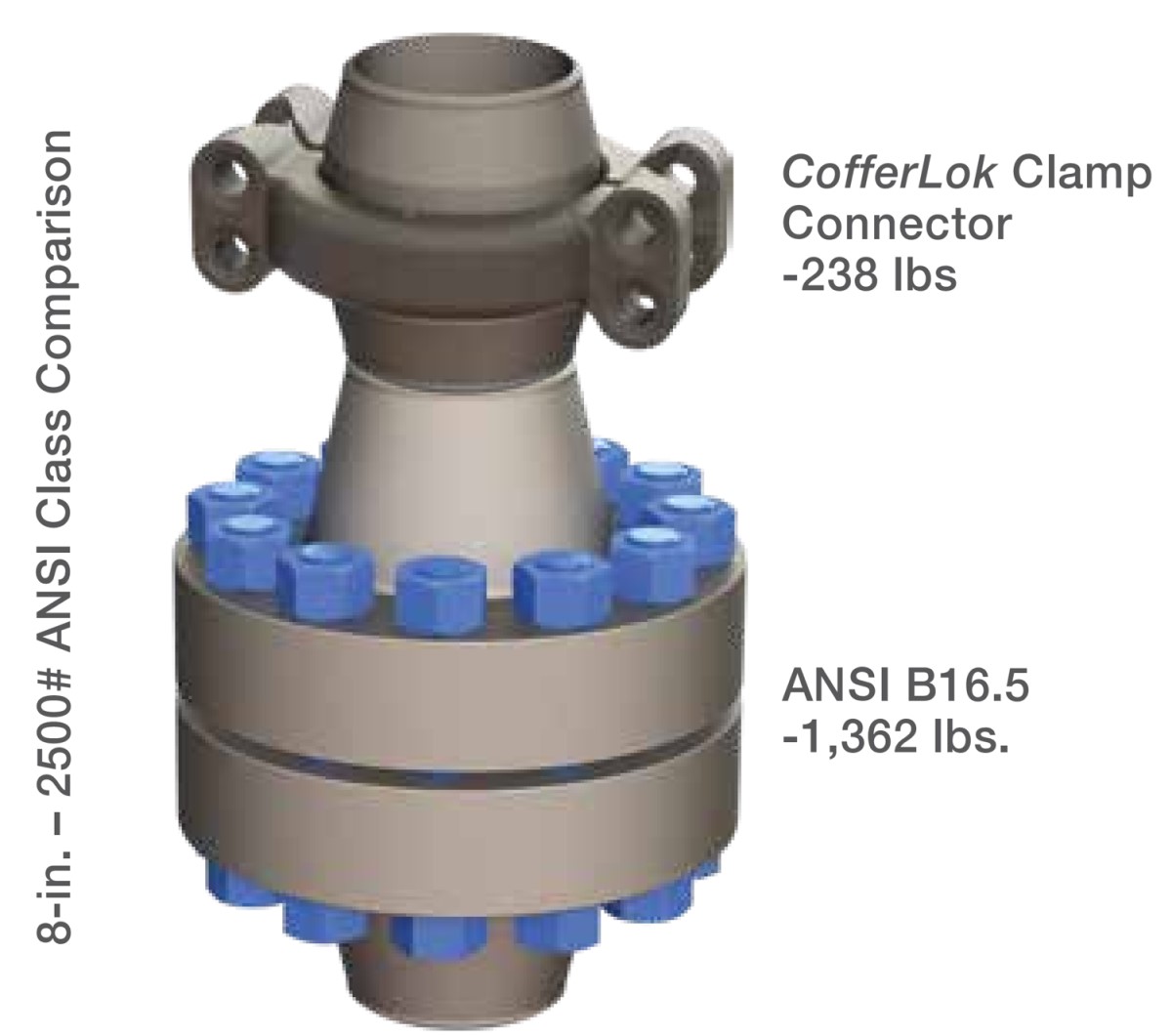

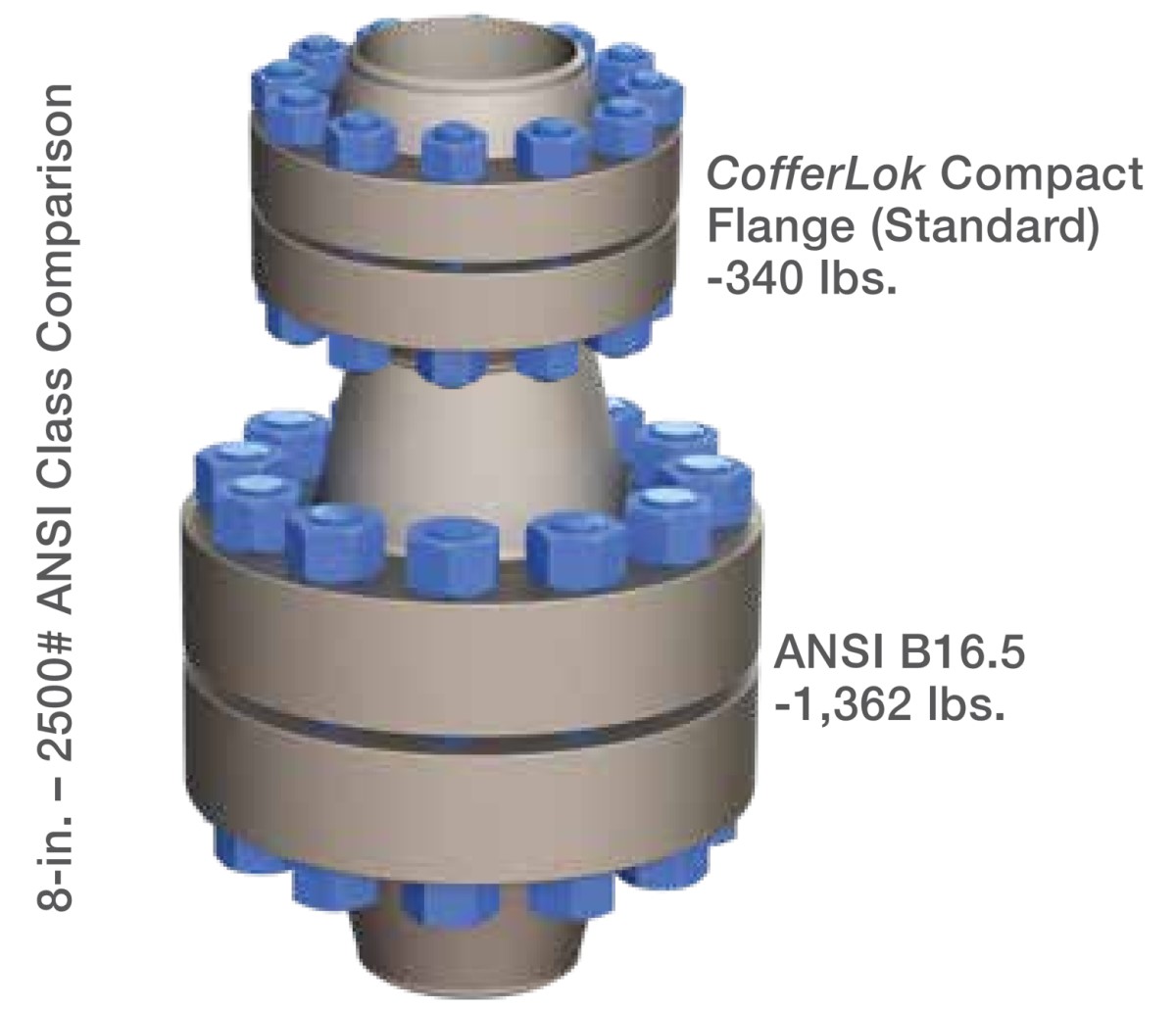

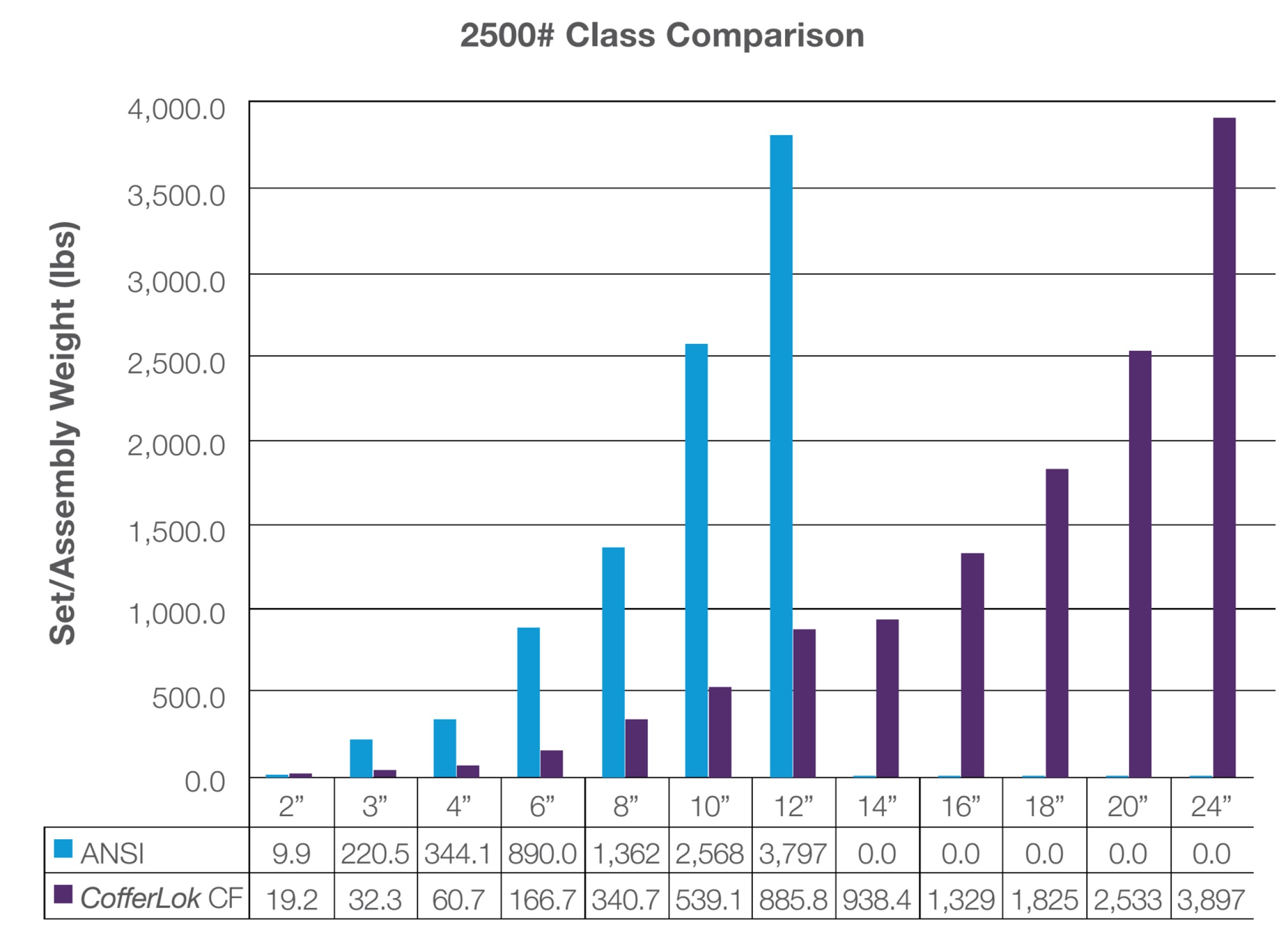

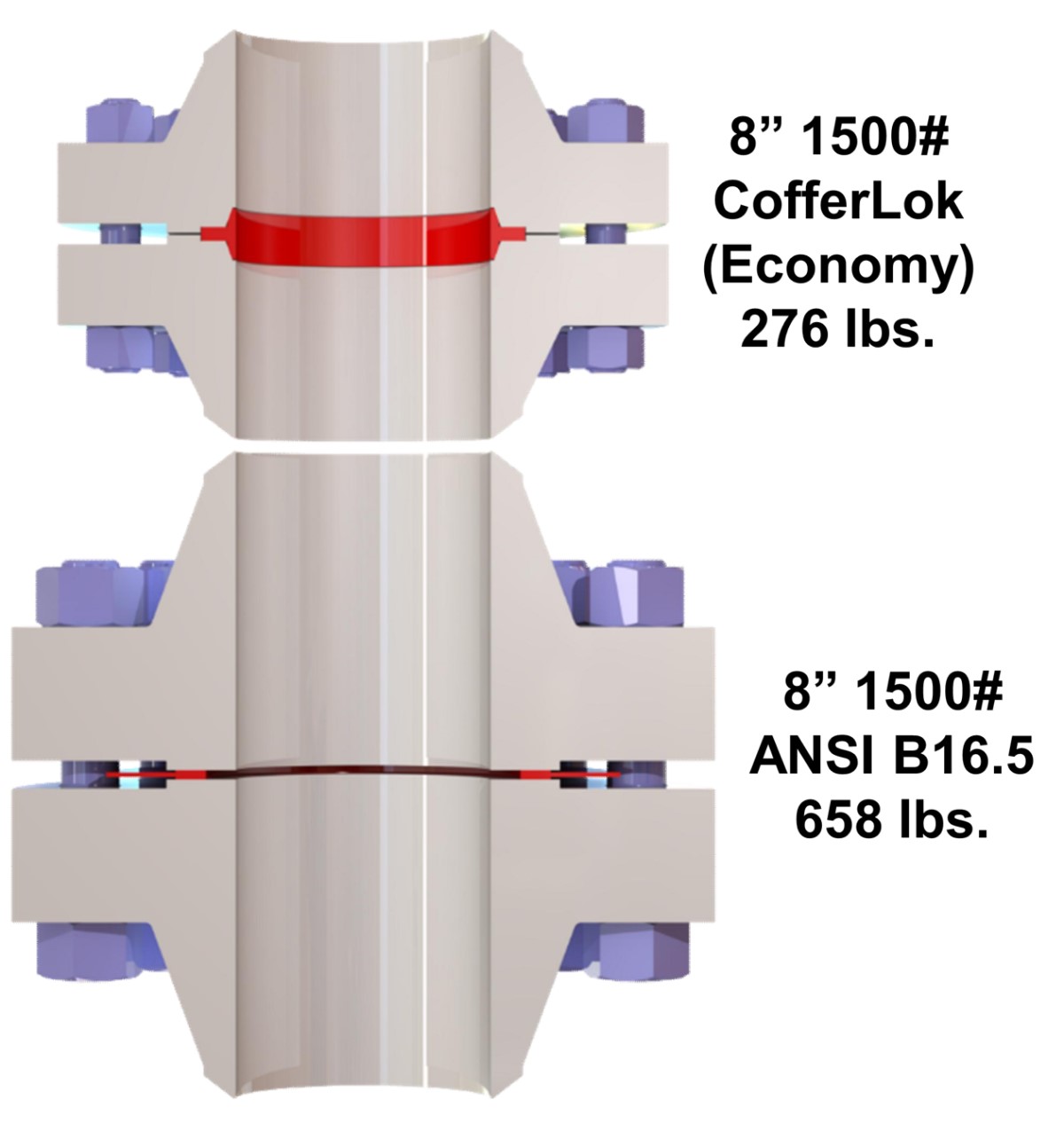

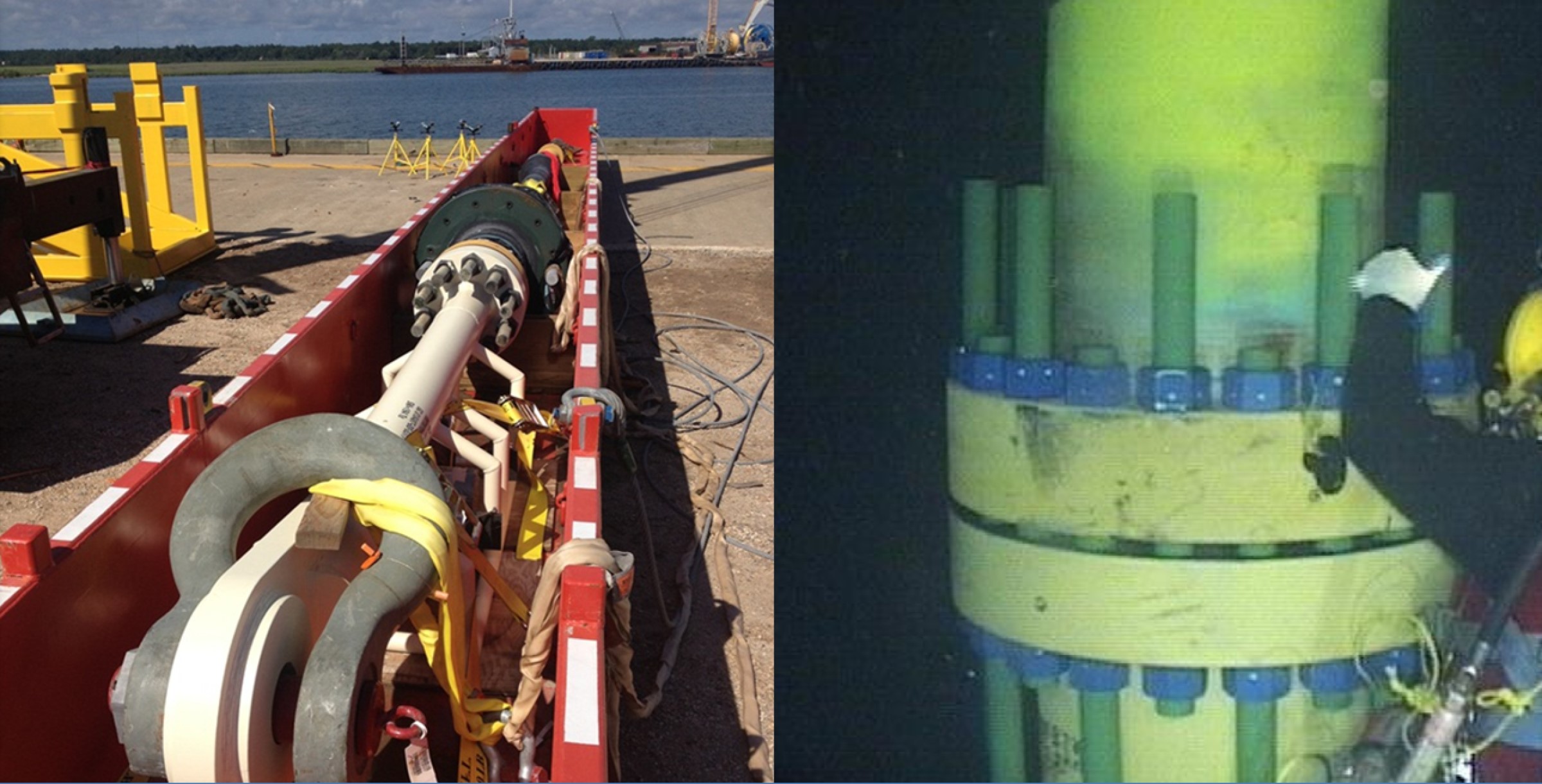

Taper-Lok and CofferLok Compact Engineered Connectors can handle high fatigue and high bending moments. We can optimize the design of the connector as needed to meet project requirements. The design usually has less weight and a smaller outside diameter than ANSI or API flanges. In addition, our connectors typically use smaller bolt sizes and less bolts that allow for easier handling and quicker make up times. Even faster make-up times can be realized when using our Taper-Lok spherical nose feature that allows for 2-3 degrees of misalignment on weldneck and swivel designs. Applications include pipelines, flowlines, risers, spools, tapered stress joints and flex joints.

Quick Assembly

Engineered Connector systems typically use fewer and smaller bolts in comparison to ANSI or API flanges. Our catalog of connectors includes clamps that only require four bolts and flange connectors that are self-aligning and allow for misalignment.

Less Cost, Less Size and More Reliable

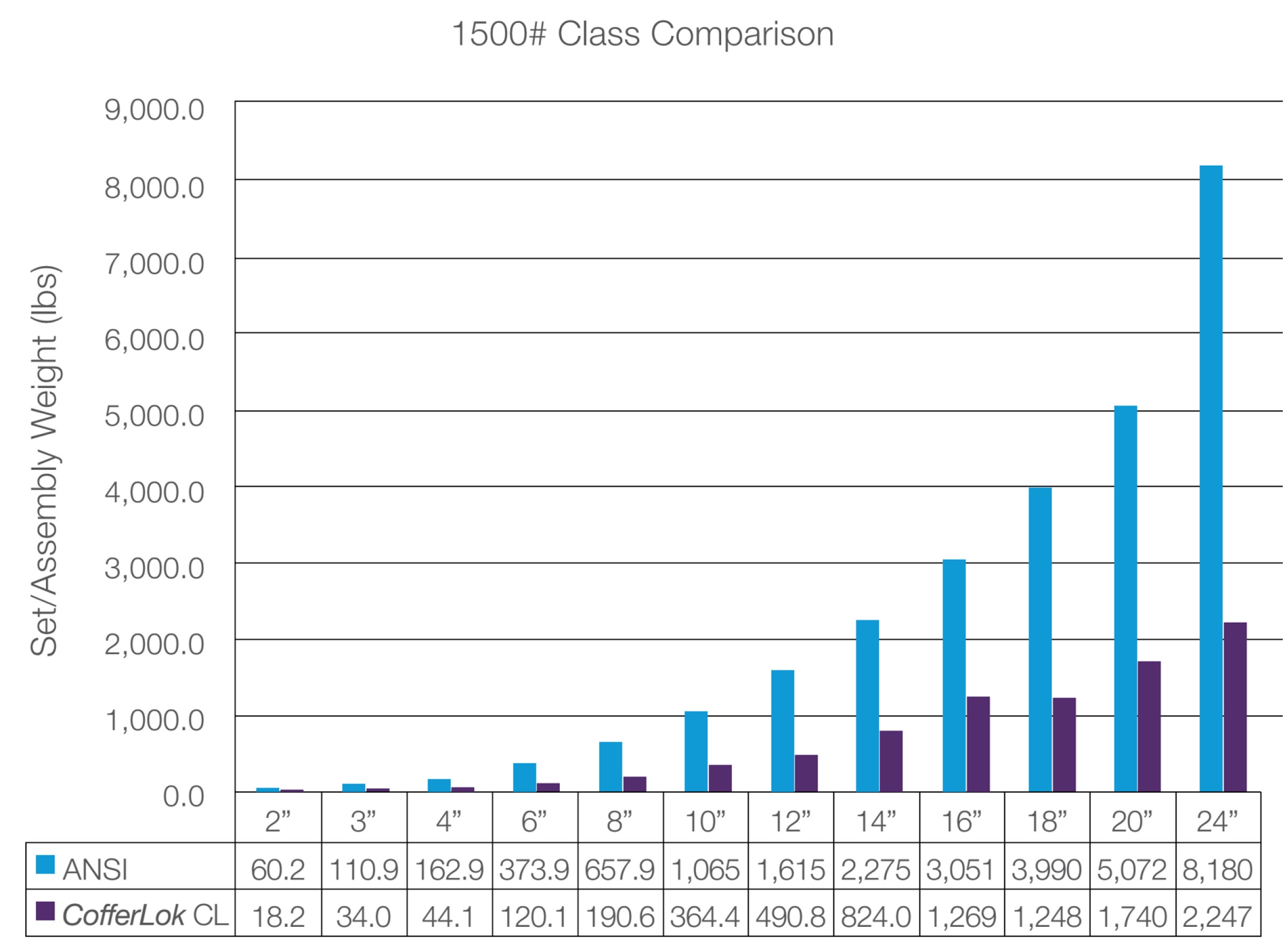

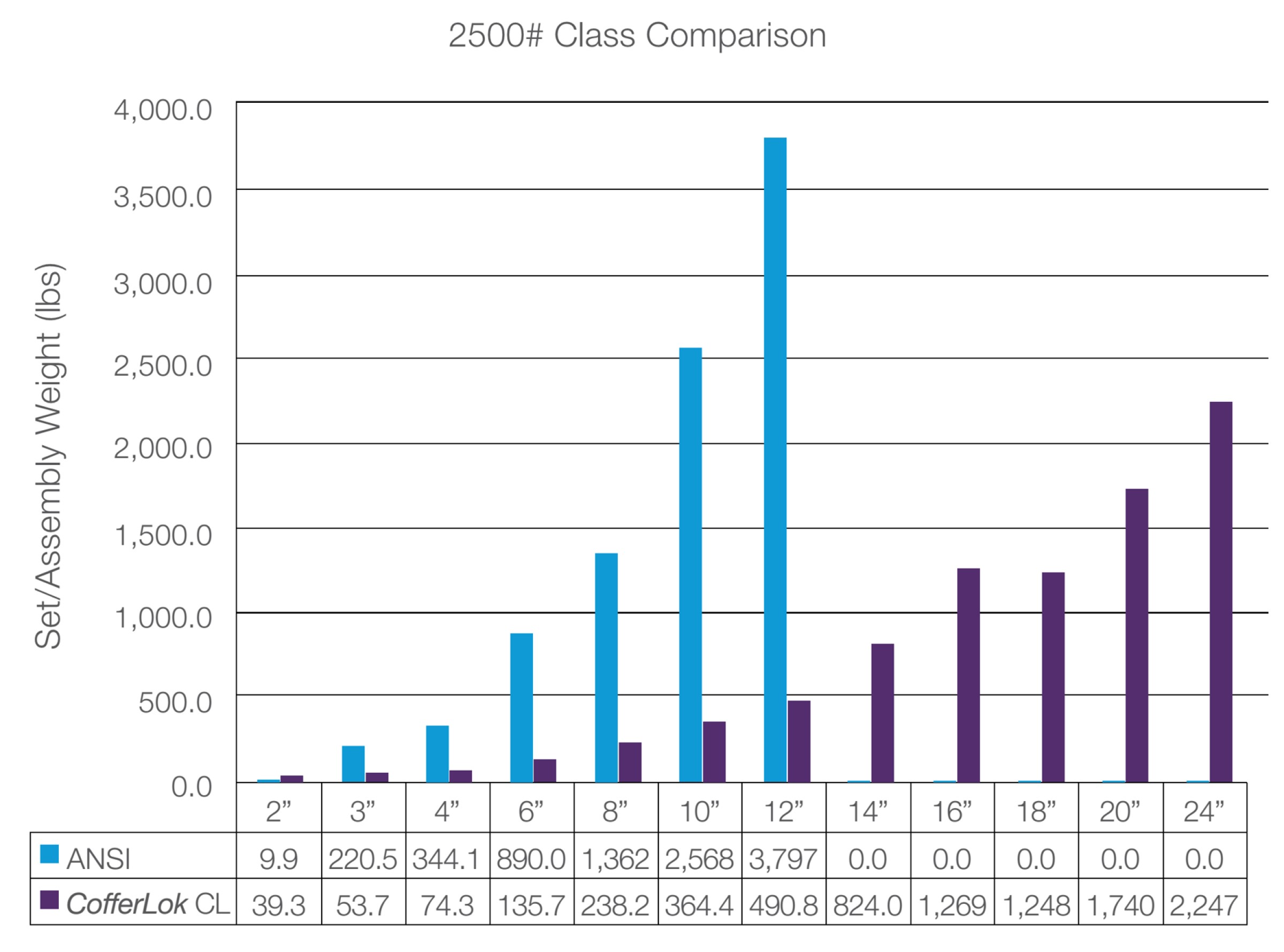

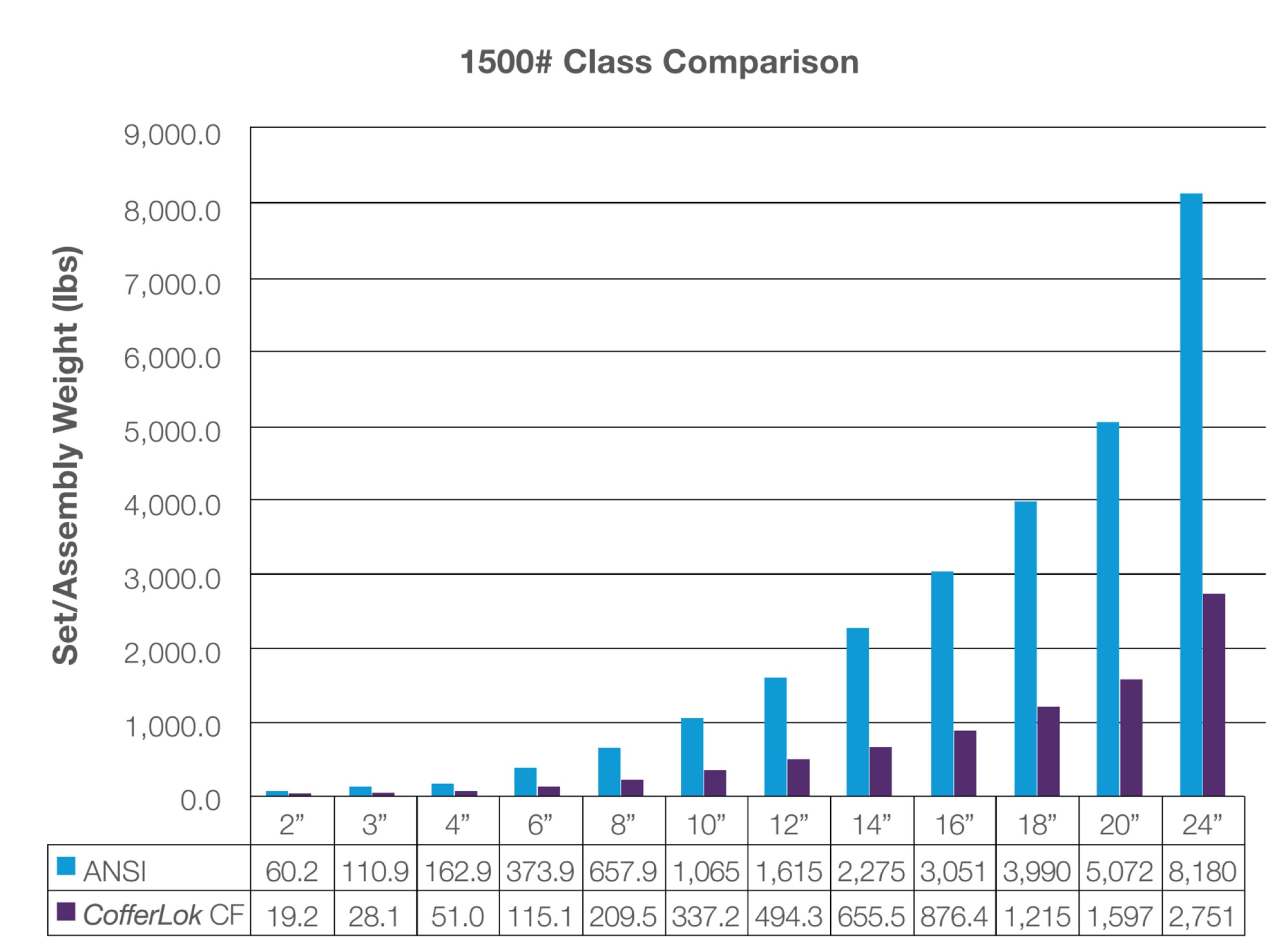

Taper-Lok and CofferLok Connectors have many advantages over ANSI B16.5 flanges.

Weight Savings –Cost savings of $7 -$10 of capital cost for each 1 lb. (.45 kg) reduction in offshore weight. Less pipe weight to support. Less freight costs. Less weight for skids and cranes (Smaller lifting barges). Less support needed for heavy installation. Easier handling during fabrication and fit up.

Space Savings –Pipe runs are closer together. More room for process equipment. More room for future tie-backs.

Maintenance Savings –No leaks (how much does a leak cost?). No “hot work”, faster “through put” and reduces shutdowns. No corrosion/erosion problems. Flange equipment and valves with “weld integrity”.

Inventory Savings –Seal rings are designed to be reused

High Pressure and/or High Temperature Applications

Our Engineered Connector systems have applications in high pressure and/or high temperature where they outperform ANSI and API flanges in terms of reliability and leak free service. Pressures up to 20K psi and temperatures up to 1,500 Deg F.