Heat Exchanger Connectors

Heat Exchanger Connectors

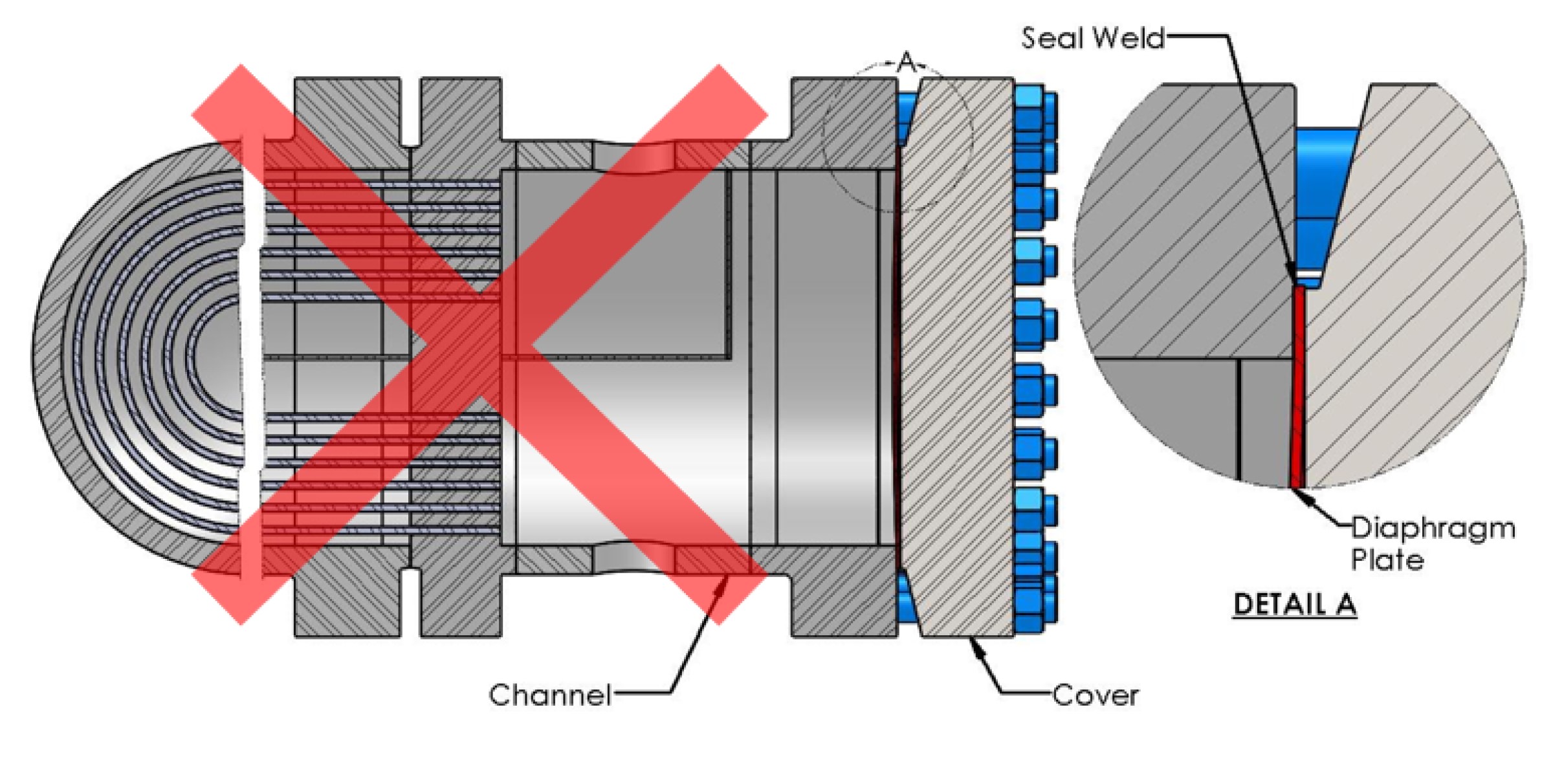

Eliminate Welded Diaphragm Seal Design

Existing Heat Exchangers that have chronic leak issues, or are using sealing technology that is difficult to quickly open/close, are ideal for Taper-Lok®.

Leaking welded diaphragms of high pressure heat exchangers in hydrotreating and hydro-processing service units are a serious problem for the petrochemical industry. The welded diaphragm is located just in front of the tube side cover plate and is highly stressed due to the combination of high pressure hoop stress and large compressive forces from the cover plate bolting. The strenuous environment and thermal cycles stimulate corrosion cracking at the weld of the diaphragm, therefore causing a path for leaks. Reoccurring equipment failures demand that the units be taken out of service for weld repairs, temporary clamp installation, or welding of new metal diaphragms. Heat exchanger repairs are very costly due to the decommissioning of the entire drive train, as well as the lost opportunity from extended downtime.

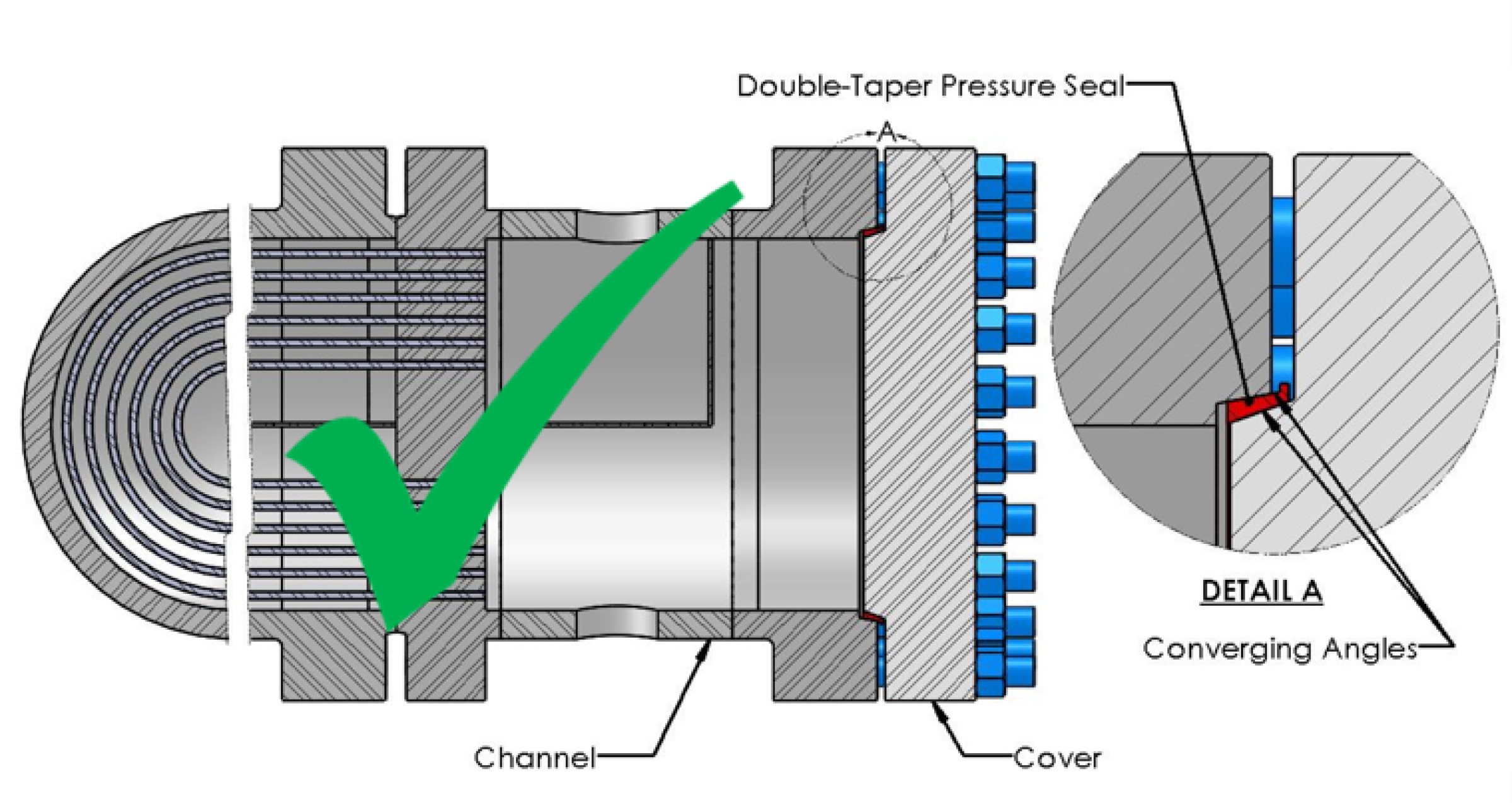

Replace with Taper-Lok®

Eliminate all problematic welding and simplify the design by using the Taper-Lok® seal. The basic converging angle seal geometry wedges itself between the cover plate and channel wall to create a pressure tight seal. The seal is self-energizing and pressure-enhanced, which results in an even tighter seal and reliable leak-free service.

The elimination of the weld also allows opening/closing of the exchanger to be up to 80% faster. As a result, our customers can typically save up to $400K each planned shutdown for each exchanger. Customers can also potentially save $Millions in lost production during unplanned shutdowns due to less cost for parts, service and less days of downtime.

We can retrofit your existing heat exchanger that has a welded diaphragm seal design and change it to Taper-Lok during your next planned or unplanned shut down. The retrofit process can be done during regularly scheduled maintenance outages.

We can also work with heat exchanger manufacturers to design the channel flange and tube sheet with our incredible and simple design.

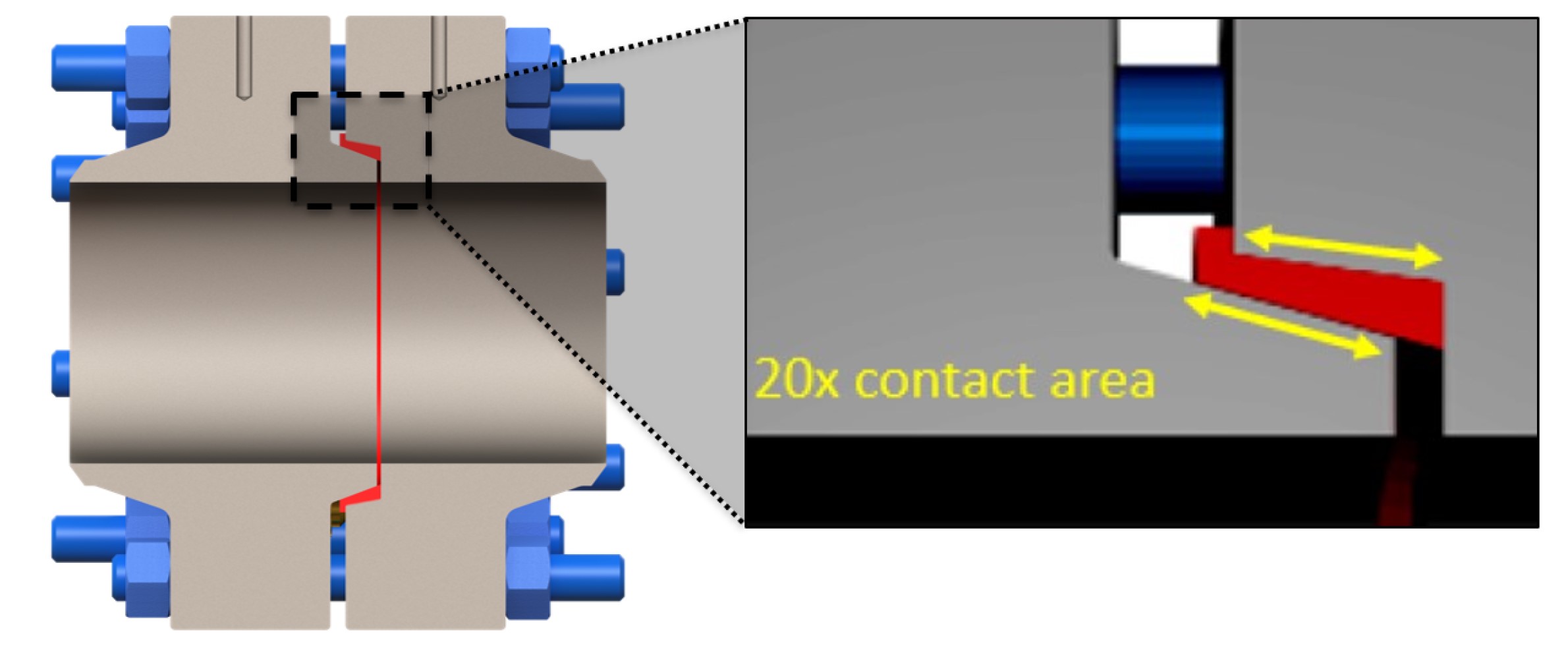

Taper-Lok Wide-Area Seal Technology

Taper-Lok Connectors metal-to-metal seal ring technology offers leak-free reliability over traditional ANSI and API gaskets. Our seal rings offer the equivalency of welded joint integrity and can be used in critical and chronic leak areas. Many “metal to metal” ring type connections rely on a narrow band of contact. In principle, this will be enough, but in practice, in field conditions they are easily damaged. Taper-Lok incorporates a Wide Area Seal that is up to 20 times the contact area of other metal to metal seals. Ensuring a robust and forgiving connection that can easily withstand the rigors of repeated job site connections in tough conditions.